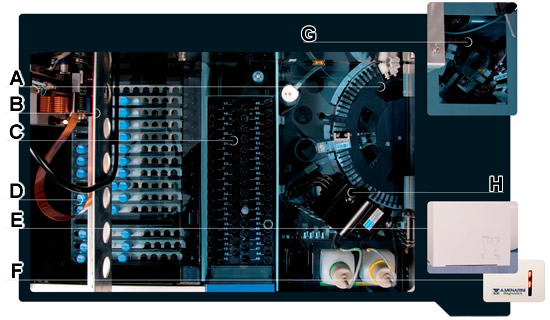

| A. |

A thermo-regulated carousel set at 37°C with 90 positions for disposable cuvettes. A spectrophotometer for measuring absorbance in certain immunoassay reactions is incorporated into the carousel |

| B. |

A pipetting arm that pipettes both reagents and samples |

| C. |

A sample tray with 64 positions for samples, calibrators and controls |

| D. |

A refrigerated reagent compartment, consisting of 15 rails containing the immunoassay reagent racks. The reagent cartridges are stored in the refrigerated reagent compartment between 12 and 15°C while the analyzer is operating, and between 8 and 10°C in standby mode |

| E. |

An automatic cuvette loader, holding 960cuvettes at a time (pre-formed as a cube) |

| F. |

Two barcode readers (one located on the front face of the analyzer, the other integrated into the reagent compartment) identify samples, ancillary reagents and reagent cartridges |

| G. |

Four washers for washing magnetic particles |

| H. |

A luminometer measuring luminescence in immunoassay reactions (directly in the cuvette) |

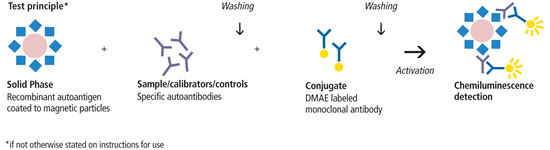

AN INNOVATIVE OPERATING PRINCIPLE CLIA (Chemiluminescence enzyme immunoassay) based tecnology

The assay is based on a two-step indirect chemiluminescent method that generates quantitative results. This particular technique uses autoantigen-coated magnetic particles as solid phase and an antibody labeled with a dimethyl acridinium ester (DMAE) as detection marker. The use of high quality antigens and large coated surfaces provides excellent sensitivity in

Zenit RA immunoassays.

- In the first incubation phase, specific autoantibodies present either in the sample, calibrators or controls bind to the immobilized antigen

- In the second incubation phase the DMAE conjugate reacts with the coated magnetic particle-autoantibody complexes

- Non-bound material is washed away after every incubation step

- Chemiluminescence is activated by the addition of trigger solutions:

A (hydrogen peroxide) and B (an alkaline solution), resulting in oxidation of the ester to an excited form. Return to a stable state is accompanied by the emission of light, which is measured and expressed in Relative Light Units (RLU)

- The signal is directly proportional to the concentration of specific autoantibodies in the samples, calibrators or controls

AN OPTIMIZED WORKFLOW

Let’s push the start button…

- Samples and reagents are aspirated using a probe equipped to detect liquid level using capacitance. The sample and reagents are pipetted in accordance with the validated parameters for each assay and transferred into a cuvette where the reaction takes place

- Reaction cuvettes are then incubated on the carousel at 37°C for 10 minutes

- The probe is rinsed internally and externally between each sample to eliminate any risk of contamination

- The cuvettes are transferred to the washing module where magnets hold the solid phase (magnetic particles) during washing

- Conjugate is added to the cuvettes and they are transferred to the carousel for another incubation at 37°C for 10 minutes

- After this last incubation step, another washing is performed in the washing module as mentioned earlier

- The cuvette is then transferred to the luminometer where trigger reagents are added to produce luminescence

- When measurement is complete, cuvettes are automatically ejected into a re-usable solid waste tray

THE KEY FEATURES AT A GLANCE

Flexibility

- Various work modalities: Random access, batch mode and STAT priority function for urgent samples

- Up to 15 different simultaneous immunoassays

- Continuous access to samples, reagents, consumables and parts

- 64 positions for samples, controls or calibrators

- Several disciplines can be processed in one run (Autoimmunity but also Infectiology)

- Patient-specific test profiles

- On-board dilution and pre-treatment of samples

- Calibration stable for 4 weeks

- Asynchronous management of samples

- Reagent cartridges on board in a refrigerated area

- Primary and secondary tubes accepted: 5, 7, 10 ml tubes and pediatric micro-cups

- Reflex testing capability

Accuracy, Reproducibility…

- Highly reliable results:

- Stored master curve

- 2-point recalibration method

- Use of coated-microparticles instead of classical coated-cuvettes (providing more uniform and extensive coating)

… and quality/safety of the results

- Flashing light drawer-system (to prevent interruption of procedures and safeguard results)

- One cuvette per test (to avoid potential cross contamination)

- Probe rinsing between each sample

- Clot detection system

Efficiency

- Short time to first result: within 25 minutes

- High throughput: 70tests/hour

- Continuous loading of bar-coded samples and reagents for peak workloads

- Workload management for optimal throughput: ideal for labs performing 50 to 400tests per day

- Sample volumes as low as 4 μl in some assays

- Calibrators and controls included

- Ready to use reagent cartridges

Simplicity

- Load and walk away (960 cuvettes on board, automatic cuvette loader, ancillary reagents on board for more than 1000 tests)

- Intuitive user interface

- Barcode reading for all reagents and samples

Computerized functionality

The analyzer is connected to a computer via an Ethernet link.

Workflow is programmed with dedicated software that performs the following functions:

- Management of reagent, calibrator and control lots

- Quality controls (Levey-Jennings and Westgard)

- Management of ancillary reagents

- Full traceability of samples, reagents and operators

- Transfer of results to a centralized computer system

- Automatic wakeup and shutdown

- Remote maintenance connection

Lab-Friendly design

- Small size (L 105 cm x H 70 cm x W 75 cm)

- Benchtop

- Flashing light drawer-system